When it comes to lighting solutions, LED strip lights have become increasingly popular due to their versatility, energy efficiency, and aesthetic appeal. However, with a wide array of options available in the market, choosing the right LED strip lights can be a daunting task. In this comprehensive guide, we will explore the key considerations and factors that can help you select high-quality LED strip lights that meet your specific requirements and ensure optimal performance. we will provide you with an extensive and informative guide to make your LED strip light purchasing experience a success.

Understanding LED Strip Lights Specifications

To make an informed decision, it is crucial to understand the various specifications associated with LED strip lights. These specifications include:

1. Brightness (Lumen Output):

The brightness of an LED strip light is measured in lumens (lm) and indicates the amount of light it emits. Higher lumen output results in brighter illumination. Ensure that the strips you choose are bright enough for your application’s intention. Assessing the lumen output is essential to make the LED strip light meets your desired level of brightness for the intended application.

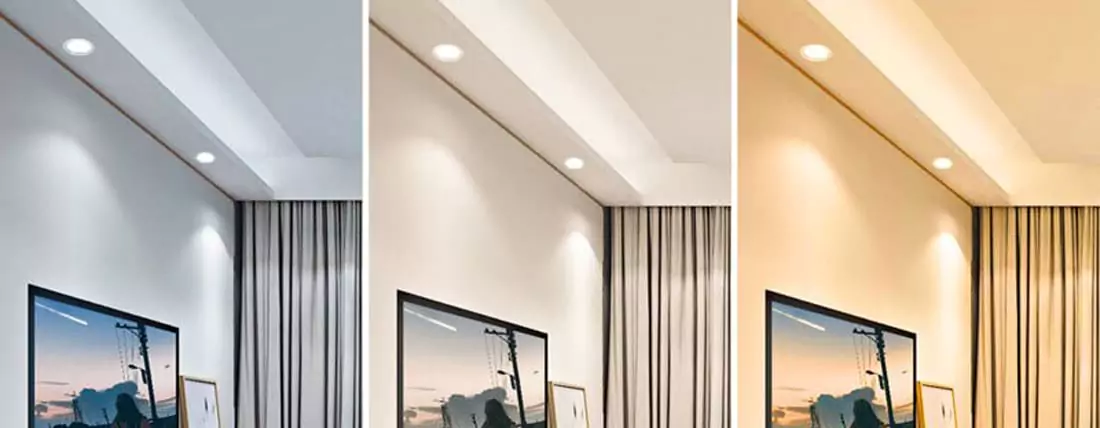

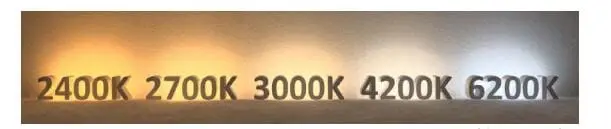

2. Color Temperature:

LED strip lights come in different color temperatures, measured in Kelvin (K). Lower Kelvin values (e.g., 2700K) produce warm white light, while higher values (e.g., 6000K) create cool white light. Choosing the appropriate color temperature helps create the desired ambiance and atmosphere in your space. Not all white light appears the same. Correlated Color temperature (CCT) defines the color appearance of a white light. CCT is defined in degrees Kelvin. Most white lights fall in a spectrum between 1800K and 6500K. When falling below 3000K, the light looks noticeably warmer like a candle. On the other end of the spectrum, the lights have a blue-ish tint and cooler tone when passing above 6500K. Some color temperatures will better suit your design than others. Choose complementary highlighting tones and look at example photos to find which you feel will look the best.

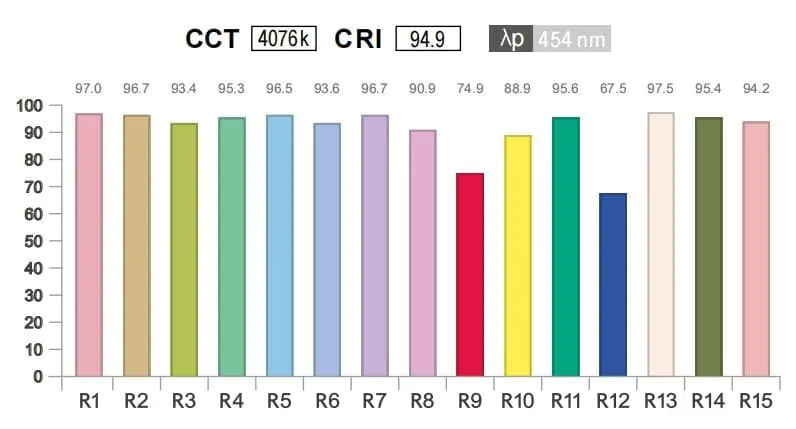

3. Color Rendering Index (CRI):

The Color Rendering Index (CRI), also known by some as color

accuracy, is a term of measurement of how natural the light

given off by a source looks in comparison to the sun. Have

you ever purchased a red towel or dress in the store and when

you try it on at home or wear it outside in the sun it looks different? This is because the CRI is different between the two light sources. High CRI LEDs will show an object‘s true pure and vibrant color.The highest CRI is 100 (like the sun). Great CRI is measured above 80 while excellent CRI measures over 90. A higher CRI value indicates better color rendering and ensures that colors appear true and vibrant. Look for LED strip lights with a CRI of 80 or above for optimal color accuracy.

4. LEDs Types:

Different LED types, such as SMD (Surface Mounted Device) and COB (Chip-on-Board), offer varying performance characteristics. Assessing the quality of LED chips used in the strip lights is crucial as it directly impacts brightness, color consistency, and longevity.

LED Type |

Dimensions |

CCT |

Emitting Color |

Luminous Flux | CRI |

VF |

IF |

Beam Angle |

SMD3528 |

3.5*2.8*1.8mm |

1800-12000K |

W/R/G/B/Y/A/PK/UV |

CRI80: 7-8lm CR90: 6-7lm CRI95: 6-7lm |

80/90/95 Ra |

3.0-3.2V |

20mA |

120° |

SMD5050 |

5.0*5.0*1.6mm |

W/R/G/B/Y/A/PK/UV |

CRI80: 22-24lm CR90: 18-20lm CRI95: 16-18lm |

3.0-3.2V |

60mA |

|||

| SMD5050RGB | 5.0*5.0*1.6mm | RGB 3 in 1 | / | 3.0-3.2V | 60mA | |||

| SMD5050RGBW | 5.0*5.0*1.6mm | RGBW 4 in 1 | / | 3.0-3.2V | 80mA | |||

| SMD5050RGBWW | 5.0*5.0*1.6mm | RGBWW 5 in 1 | / | 3.0-3.2V | 100mA | |||

SMD2835 |

2.8*3.5*0.8mm |

W/R/G/B/Y/A/PK/UV |

CRI80: 22-24lm CR90: 18-20lm CRI95: 16-18lm |

3.0-3.2V |

60mA |

|||

SMD3014 |

3.0*1.4*0.8mm |

W/R/G/B/Y/A/PK/UV |

CRI80: 10-13lm CR90: 9-12lm CRI95: 9-10lm |

2.8-3.2V |

30mA |

|||

SMD5730 |

5.7*3.0*0.8mm |

White |

CRI80: 55-60lm CR90: 50-55lm CRI95: 50-52lm |

2.8-3.6V |

150mA |

|||

SMD2216 |

2.2*1.6*0.6mm |

White |

CRI80: 7-9lm CR90: 7-8lm CRI95: 6-7lm |

2.8-3.2V |

30mA |

Evaluating LED Strip Lights Quality

Ensuring the quality of LED strip lights is paramount to their long-term performance and durability. Consider the following factors when assessing the quality:

1) LED Strip Light Manufacturer

Choose reputable manufacturers with a proven track record of producing high-quality LED strip lights. Reliable manufacturers invest in research and development, adhere to strict quality control measures, and provide comprehensive warranties for their products.

2) Quality of Copper Wire in PCB

The performance of an LED strip is greatly influenced by the quality of the copper wire used in its PCB (Printed Circuit Board). Copper wires serve as the lifeline of the LED strip, facilitating the seamless flow of current to all the components installed on the PCB. Opting for high-quality copper wire ensures efficient power transmission, leading to reliable and consistent performance of the LED strip.

When selecting LED light strips, it is important to pay attention to the thickness of the copper wire. Thin or substandard copper wire may restrict the passage of current, resulting in LED strips that fail to function or suffer from voltage drop issues. Additionally, low-quality copper wire can impede the flow of current, negatively impacting the overall functionality and longevity of the LED strip.

3) Quality of Phosphor in LED

Phosphor, a crucial component of LEDs, significantly influences the quality of light emitted by LED strip lights. It is responsible for enhancing the fluorescence of light, particularly in producing pure white illumination. Choosing LED light strips with high-quality phosphor is essential to achieve optimal brightness and color accuracy.

Inferior phosphor can have detrimental effects on the performance of LED lights. It may cause the lights to appear dimmer and compromise the purity of the emitted light. Over time, poor-quality phosphor can lead to color degradation, resulting in a less vibrant lighting experience. Therefore, investing in LED light strips with superior phosphor ensures long-lasting, vibrant, and visually appealing lighting solutions.

4) Component Placement

Proper component placement on the PCB is crucial for the seamless functioning of LED light strips. Each LED component must be accurately positioned to ensure optimal performance and longevity. Deviations or errors in component placement can lead to LED strips that fail to work or exhibit subpar performance.

To achieve precise and reliable component placement, advanced technologies such as pick & place robots are often employed. These automated systems ensure that each component is positioned correctly, guaranteeing optimal electrical connections and efficient operation of the LED strip.

Another critical aspect of component placement is avoiding the combination of different-sized LEDs on a single strip. Although mixing LEDs of various sizes may seem like a cost-effective approach to achieve brighter illumination, it can negatively impact the efficiency and longevity of the LED strip. Different-sized LEDs have varying electrical characteristics, which can lead to imbalances in power distribution and accelerated degradation of phosphor. Consequently, LED light strips with mixed-sized LEDs are more likely to have shorter lifespans and require frequent replacements, resulting in higher long-term costs.

5) Component Quality

The quality of components used in LED light strips is a fundamental determinant of their overall performance, durability, and reliability. LED strips that incorporate high-quality LEDs, resistors, and PCBs outshine their counterparts in terms of performance and longevity.

LEDs of superior quality exhibit excellent color consistency, ensuring that the emitted light remains uniform and visually pleasing. They

also have longer lifespans, providing reliable and durable lighting solutions. In contrast, LED light strips with low-quality LEDs may suffer from color inconsistency, resulting in an uneven lighting experience. Furthermore, substandard LEDs are more prone to early degradation and failure, leading to diminished brightness and shorter lifespan.

In addition to LEDs, the quality of resistors and PCBs used in LED light strips is equally important. Faulty or subpar resistors can disrupt the flow of current, leading to inefficient power distribution and potential overheating of the LED strip. Similarly, low-quality PCBs may hinder proper component integration, compromising the overall functionality and reliability of the LED strip.

By investing in LED light strips that incorporate top-quality components, you can ensure a hassle-free lighting experience with optimal performance and extended lifespan. It is crucial to conduct thorough research, read customer reviews, and seek recommendations from trusted sources before making a purchasing decision. Taking these steps will enable you to select LED light strips that not only meet your lighting requirements but also offer long-term value and satisfaction.

6) Heat Dissipation

Heat dissipation is crucial for maintaining the longevity of LED strip lights. Look for strip lights with proper heat sinks or aluminum profiles that effectively dissipate heat, preventing overheating and ensuring optimal performance.

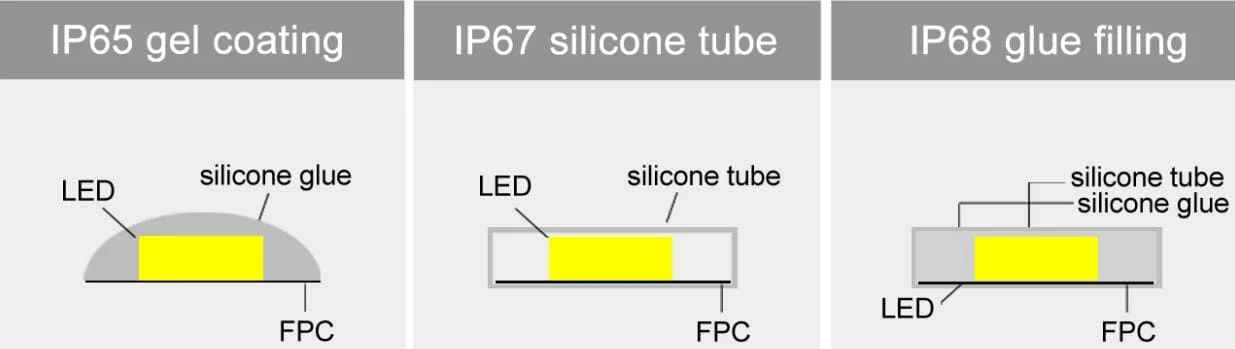

7) Waterproof Rating

If you plan to install LED strip lights in areas prone to moisture or outdoor environments, consider strip lights with appropriate waterproof ratings. These ratings, such as IP65 or IP67, indicate the level of protection against dust and water ingress.

8) Certifications and Compliance

Look for LED strip lights that meet industry standards and certifications, such as UL or CE. These certifications ensure that the strip lights comply with safety and performance regulations.

Determining Suitable LED Strip Lights Types

Choosing the right type of LED strip lights depends on your specific lighting requirements and installation conditions. Consider the following factors:

1. Brightness and Light Output: Evaluate the desired brightness level and the space you want to illuminate. Depending on your needs, you can select from a range of LED strip lights, including high-brightness strips, medium-brightness strips, or low-brightness decorative strips.

2. Color Options: LED strip lights are available in a variety of colors, including single-color (e.g., white, warm white, red, blue, green) and multicolor RGB or RGBW options. Determine whether you require a specific color or dynamic color-changing capabilities.

3. Flexibility and Bendability: If you require LED strip lights for curved or irregular surfaces, choose flexible strips that can bend and conform to the desired shape without compromising their functionality.

4. Cutting and Length Customization: LED strip lights often come with cutting marks, allowing you to trim or customize the length according to your specific project requirements. Ensure that the strip lights can be easily cut without affecting their functionality or warranty.

5. Power Supply and Voltage Compatibility: LED strip lights typically operate on DC (Direct Current) power supply. Ensure that the voltage and power requirements of the strip lights align with your existing power sources or consider using compatible LED drivers or transformers.

Practical Installation Tips and Techniques

Proper installation plays a vital role in maximizing the performance and lifespan of LED strip lights. Consider the following installation tips:

- Surface Preparation: Ensure that the surface where you plan to install the LED strip lights is clean, dry, and free from dust or debris. This promotes better adhesion and prevents the strip lights from peeling or detaching over time.

- Adhesive Backing and Mounting Options: LED strip lights typically feature adhesive backing for easy installation. However, for long-term or heavy-duty applications, consider additional mounting options such as clips, brackets, or aluminum profiles to provide additional support and stability.

- Power Connection and Wiring: Follow the manufacturer’s instructions and safety guidelines for proper power connection. Use appropriate connectors, soldering techniques, or snap-on connectors to ensure secure and reliable electrical connections.

- Dimming and Control Options: LED strip lights offer various dimming and control options, including manual dimmers, wireless remotes, or smartphone-controlled systems. Consider the desired level of control and convenience when selecting the appropriate dimming and control options for your LED strip lights.

- Maintenance and Cleaning: Regular maintenance and cleaning of LED strip lights ensure optimal performance and longevity. Use a soft, lint-free cloth or a mild cleaning solution to gently remove any dirt or residue from the strip lights.

Conclusion

Choosing high-quality LED strip lights requires careful consideration of various factors, including specifications, quality, type, and installation requirements. By understanding the specifications, evaluating quality indicators, determining suitable types, and following practical installation tips, you can confidently select LED strip lights that meet your specific lighting needs. Remember to source your LED strip lights from reputable manufacturers or trusted suppliers to ensure superior performance, longevity, and overall satisfaction. Illuminate your spaces with brilliance and energy efficiency by making informed choices in your LED strip light purchases.

Author

-

I'm Joseph, the Co-founder of CST Lighting, bringing over a decade of expertise in the LED lighting industry. With a strong focus on product marketing, I am dedicated to staying at the forefront of market trends, constantly enhancing my knowledge and skills to deliver top-notch products and services to our clients. Through our insightful blog posts, we strive to share our expertise, guiding readers through the ever-evolving landscape of LED lighting. Learn more via my linkedin profile https://www.linkedin.com/in/ledcst-joseph/

View all posts