Introduction

Underground mines are dark, small, and potentially dangerous. Therefore, effective lighting is very important for safety and efficiency. Poor lighting can increase the risk of accidents such as falls or crashes, or people making mistakes. However, well-planned lighting can enhance visibility, reduce accidents, and boost worker confidence and productivity.

This blog post is a simple guide to choosing the right underground mine lighting. We’ll talk about what you need to think about when choosing lights, the different kinds of lights you can use, and some tips for good lighting design. We’ll also give advice on how to keep your lights working well and what to do if something goes wrong.

If you are responsible for the lighting in an underground mine, we encourage you to read this blog post to learn how to choose the right lighting for your needs.

Factors to Consider When Choosing Underground Mine Lighting

Safety

Good lighting is very important to keep underground miners safe. Poor lighting can cause many dangers, including:

• Reduced visibility: In dark environments, workers may struggle to identify hazards, such as uneven walkways, unstable machinery, or falling rocks. This can increase the risk of slips, trips, falls, and other accidents.

• Glare: Too much brightness can make eyes tired and sometimes even cause temporary blindness. This can make it hard for workers to think clearly and react quickly, leading to more accidents.

• Shadowing: Bad lighting can cause shadows that hide potential hazards, making it difficult for workers to navigate safely and perform tasks effectively.

To reduce these risks and put worker safety first, underground mine lighting should adhere to the following principles:

• Illumination of hazards: Lighting should be placed in a way that it highlights any possible dangers, such as walkways, machinery, and working areas, ensuring that workers can clearly identify and avoid them.

• Reduced glare: Lighting should be made to reduce brightness by spreading light evenly and stopping direct light from hitting workers’ eyes.

• Uniform lighting distribution: Lighting should be distributed uniformly throughout the mine, eliminating dark spots and creating a consistent level of illumination.

• Compliance with safety regulations: Underground mine lighting systems must comply with all applicable safety regulations and industry standards, such as those set forth by the National Institute for Occupational Safety and Health (NIOSH) and the Mine Safety and Health Administration (MSHA).

• Emergency Lighting: Underground mines need good emergency lighting systems. If there’s a power cut or if miners need to leave quickly, the lights will help them find their way to the exit or safe areas. These lights should have their own power supply and be easy to spot and reach for everyone in the mine.

Efficiency

The right lighting can significantly enhance worker productivity and overall operational efficiency in underground mines. Proper lighting can:

• Improve task performance: Adequate illumination allows workers to see clearly and perform tasks with precision and accuracy, reducing errors and rework.

• Enhance decision-making: Clear visibility and reduced visual strain enable workers to make informed decisions quickly and effectively, optimizing workflows and improving productivity.

• Reduce fatigue: Well-designed lighting systems minimize glare and shadowing, reducing eye strain and fatigue, allowing workers to maintain focus and productivity throughout their shifts.

To maximize efficiency, underground mine lighting systems should incorporate energy-efficient technologies, such as LED lighting:

• Energy savings: LED lights consume significantly less energy than traditional incandescent or fluorescent lamps, reducing operational costs and the environmental impact of mine lighting.

• Long lifespan: LED lights have a much longer lifespan than traditional lamps, minimizing maintenance costs and ensuring consistent lighting performance over time.

• Durability: LED lights are resistant to shock, vibrations, and harsh environmental conditions, making them ideal for the demanding underground mining environment.

Underground Mine Lighting Feature Requirements

In addition to the factors mentioned above, underground mine lighting should also be:

• Corrosion-resistant: Underground mines are often exposed to corrosive elements, such as water, chemicals, and dust. Lighting fixtures should be made of corrosion-resistant materials, such as stainless steel or aluminum, to withstand these harsh conditions.

• Waterproof: Underground mines are also prone to flooding. Lighting fixtures should be high waterproof to protect them from damage from water.

• UV-resistant: Underground mines are often exposed to ultraviolet (UV) radiation from sunlight. Lighting fixtures should be UV-resistant to prevent fading and damage from UV rays.

• Flame-retardant: Underground mines are considered high-risk areas for fire. Lighting fixtures should be flame-retardant to help prevent the spread of fire.

By incorporating these additional features, underground mine lighting can help to further improve worker safety and reduce the risk of accidents.

Here are some specific examples of how these features can be implemented:

• Corrosion-resistant materials: Stainless steel and aluminum are both good choices for corrosion-resistant materials. They are also strong and durable, making them ideal for the demanding underground mining environment.

• Waterproof fixtures: Lighting fixtures can be made waterproof by using gaskets, seals or glue to prevent the ingress of water.

• UV-resistant coatings: UV-resistant coatings can be applied to lighting fixtures to protect them from fading and damage from UV rays.

• Flame-retardant materials: Flame-retardant materials can be used to make lighting fixtures. These materials are designed to resist the spread of fire and stop flammable materials from catching fire.

By considering all of these factors, underground mine operators can choose the right lighting system to help protect workers and ensure the safety of their operations.

Underground Mine Lighting Types and Applications

Different types of lighting commonly used in underground mines, along with their advantages and disadvantages, and recommendations for selecting the appropriate lighting type based on specific mining applications and environments:

Lighting Types and Applications

Different lights are used in underground mines for different jobs. Here’s a simple overview of the most common types of lights and what they’re best for:

1) Incandescent Lighting:

Incandescent lighting is the oldest and simplest type of electric lighting. It works by heating a wire, called a filament, which then gives off light.

Advantages:

- Instant illumination

- Warm, yellowish light

- Affordable initial cost

Disadvantages:

- Low energy efficiency

- Short lifespan

- Produces significant heat

- Limited color rendering

Applications:

- Temporary or portable lighting

- Low-wattage task lighting

2) Fluorescent Lighting:

Fluorescent lamps offer improved energy efficiency compared to incandescent lamps. They produce a brighter, more diffused light and have a longer lifespan. However, they may flicker slightly and require a ballast or starter to operate.

Advantages:

- Higher energy efficiency than incandescent lighting

- Longer lifespan than incandescent lighting

- Cooler operation than incandescent lighting

- Available in a wider range of colors

Disadvantages:

- Higher initial cost than incandescent lighting

- Flickering effect in some models

- Requires a ballast for operation

- Contains mercury, requiring proper disposal

Applications:

- General area lighting

- Task lighting in workspaces

- Emergency lighting

3) LED Lighting:

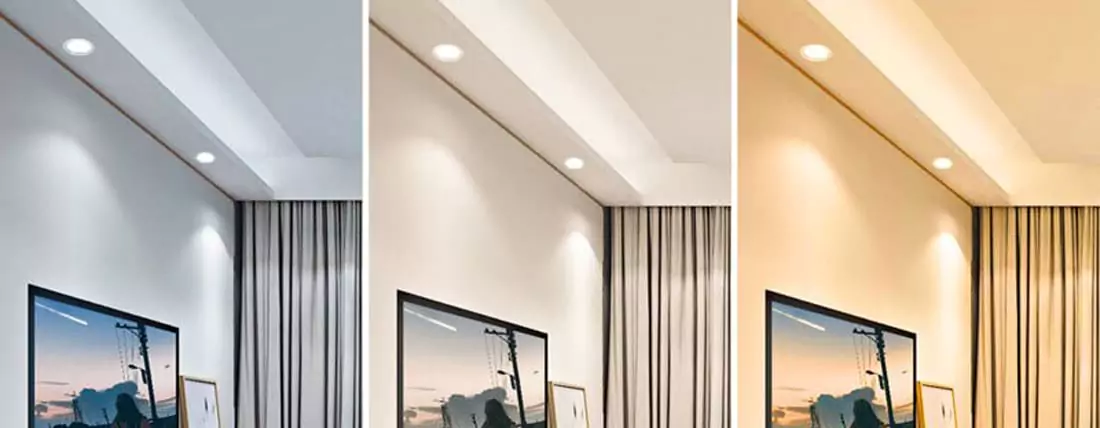

LED lights are the best and most energy-saving choice for use in underground mines. They use a lot less energy than traditional or fluorescent lights, last a very long time, and can handle shocks and vibrations. LED lights also come in many colors, from warm to cool white, to fit different needs.

Advantages:

- Highest energy efficiency among lighting options

- Extremely long lifespan

- Low heat generation

- Excellent color rendering

- Dimmable and controllable

- Durable and shock-resistant

Disadvantages:

- Highest initial cost among lighting options

- Sensitivity to temperature fluctuations

Applications:

- General area lighting

- Task lighting in hazardous areas

- Emergency lighting

- Backlighting for signage

4) High-Intensity Discharge (HID) Lighting:

HID lights, like metal halide and high-pressure sodium lights, give a lot of light for big areas. They are good for high ceilings and specific tasks. But, they take longer to get fully bright and don’t last as long as LED lights.

Advantages:

- High lumen output per watt

- Long lifespan

- Suitable for large areas

Disadvantages:

- Lower energy efficiency than LED lighting

- Longer startup and warmup time

- Color rendering varies depending on lamp type

Applications:

- High-bay lighting in large spaces

- Outdoor lighting for mining facilities

- Specialized applications, such as mineral detection

Recommendations for Selecting the Appropriate Lighting Type

The choice of lighting type depends on the specific application, environmental factors, and safety considerations.

• General Area Lighting: For general illumination of underground workspaces, LED lighting offers the best balance of energy efficiency, lifespan, and color rendering.

• Task Lighting: For specific task areas requiring precise illumination, LED and fluorescent lighting are suitable options due to their focused light output and color rendering.

• Hazardous Areas: In risky places where sparks or heat could set fire to easily burnable materials, LED lighting is the safest choice due to its low heat generation and spark-free operation.

• Emergency Lighting: For emergency illumination during power outages, LED lighting is preferred for its long lifespan, reliability, and low maintenance requirements.

• Outdoor Lighting: For outdoor areas around mining facilities, LED Lighting or HID lighting can provide high lumen output and withstand harsh weather conditions.

By carefully evaluating the specific needs of each underground mining application, operators can select the most appropriate lighting type to maximize safety, efficiency, and productivity.

Underground Mine Lighting Design and Installation

Lighting Design

Effective lighting design is crucial for optimizing safety, productivity, and worker well-being in underground mines. The design process should consider several factors to ensure adequate illumination and minimize potential hazards:

1. Lighting Levels:

Lighting levels should be tailored to the specific task or area being illuminated. Task lighting should provide sufficient illumination for workers to see clearly and perform their tasks accurately. General area lighting should provide a comfortable level of ambient illumination to enhance visibility and facilitate safe navigation.

2. Uniformity:

Uniformity refers to the consistency of lighting levels throughout the mine. Uneven lighting can create shadows and glare, making it difficult for workers to see clearly and increasing the risk of accidents. Lighting fixtures should be strategically placed to distribute light evenly and eliminate dark spots.

3. Glare Control:

Excessive glare can cause visual discomfort, fatigue, and temporary blindness. Glare can be controlled by using diffusing filters, shielding light sources, and positioning fixtures to minimize direct exposure to workers’ eyes.

4. Color Rendering:

Color rendering refers to the ability of a light source to accurately reproduce the colors of objects. In underground mines, accurate color rendering is essential for tasks that involve color identification, such as mineral sorting or safety signage. LED lighting generally offers superior color rendering compared to traditional lighting sources.

Proper Installation for Best Performance, Safety, and Longevity

Proper installation is essential for ensuring that the lighting system functions as intended and provides best performance, safety, and longevity. Key considerations for proper installation include:

- Fixture Placement:

Lighting fixtures should be strategically placed to achieve the desired lighting levels, uniformity, and glare control. Factors such as task location, ceiling height, and fixture spacing should be carefully considered.

- Fixture Selection:

Lighting fixtures should be selected based on their suitability for the specific application and environment. Factors such as ingress protection (IP) rating, durability, and compatibility with the power supply should be considered.

- Wiring Considerations:

Wiring should be properly sized, protected, and installed to ensure safety and reliability. Electrical connections should be made securely and in accordance with safety standards.

Recommendations for Lighting Placement, Fixtures, and Wiring

Here are some specific recommendations for lighting placement, fixtures, and wiring in underground mines:

Lighting Placement:

- Task lighting should be positioned directly above or near the work area to provide focused illumination.

- General area lighting should be placed strategically to provide uniform illumination throughout the workspace.

- Emergency lighting should be installed in designated escape routes and critical areas to ensure safe evacuation in case of a power outage.

Fixture Selection:

- For task lighting, consider using spot or floodlight fixtures that can be directed to the specific work area.

- For general area lighting, consider using high-bay fixtures with wide beam angles to provide uniform illumination.

- For emergency lighting, consider using self-contained, battery-powered fixtures that can operate independently of the main power supply.

Wiring Considerations:

- Use wires and cables with appropriate insulation and protection ratings for the underground environment.

- Install wires and cables in conduit or protective enclosures to prevent damage and ensure safety.

- Follow proper grounding and bonding practices to prevent electrical hazards.

By implementing these principles and recommendations, underground mine operators can design and install effective lighting systems that enhance safety, productivity, and worker well-being in their operations.

Maintenance and Troubleshooting

Taking care of underground mine lighting systems regularly is important for keeping them working well and safe. Regularly cleaning, checking, and changing parts of the lighting can make it last longer and work at its best.

Maintenance Guidelines:

- Cleaning: Regularly clean lighting fixtures to remove dirt, dust, and debris that can reduce light output and increase glare.

- Inspection: Inspect fixtures regularly for signs of damage, corrosion, or wear. Check for loose connections, damaged wires, and signs of overheating.

- Replacement: Replace damaged or worn-out components promptly to maintain system performance and safety.

Troubleshooting Procedures:

- Dim or flickering lights: Check for loose connections, damaged wiring, or failing bulbs.

- Excessive glare: Adjust fixture positions or use diffusing filters to reduce glare.

- Uneven lighting: Redistribute fixtures to achieve more uniform illumination.

- Flickering or buzzing noises: Check for loose connections or faulty ballast.

Following these maintenance guidelines and troubleshooting procedures, underground mine operators can ensure that their lighting systems continue to provide optimal performance, safety, and worker well-being.

Conclusion

Choosing the right underground mine lighting is essential for optimizing safety, efficiency, and productivity. By considering the factors discussed in this blog post, underground mine operators can select the most appropriate lighting types, design effective lighting systems, and implement proper maintenance practices to ensure a safe, productive, and well-lit underground work environment.

Resources for Further Information and Consultation

For further information and regulations on underground mine lighting, please refer to the following resources:

- National Institute for Occupational Safety and Health (NIOSH): https://www.cdc.gov/niosh/mining/features/illuminationfeature.html

- Mine Safety and Health Administration (MSHA): https://arlweb.msha.gov/epd/efsms/toolbox/illumination.pdf

- Illuminating Engineering Society of North America (IESNA): https://www.ies.org/standards/

Contact Us Today to Learn More Details!

Author

-

I'm Joseph, the Co-founder of CST Lighting, bringing over a decade of expertise in the LED lighting industry. With a strong focus on product marketing, I am dedicated to staying at the forefront of market trends, constantly enhancing my knowledge and skills to deliver top-notch products and services to our clients. Through our insightful blog posts, we strive to share our expertise, guiding readers through the ever-evolving landscape of LED lighting. Learn more via my linkedin profile https://www.linkedin.com/in/ledcst-joseph/

View all posts